Saturday morning finally came. Nothing to do but goof off. I was up in my room messing around with the model aircraft carrier I was building. I already knew I had to cut the back yard this afternoon but that didn’t bother me any. It was one of those rare Saturdays that we weren’t going out on the gulf and that bothered me more than everything. At 16 I already had almost a year of sea time and was looking for lots more. That’s why I am alive, I thought.

The door opens and in walks my dad. “Dave, let’s have a talk about your college”

Oh Crap. I thought to myself.

“It’s time to figure out what you’re going to be going in to so we can pick the right courses for you next year. Senior year is critical, Dave. “

“Uh, Well, gee, do we have to do that right now Dad I’m right in the middle of something important” I said. I knew that wouldn’t fly but I was cornered. It was the best I could do.

“Sit down, let’s go over this”: he said

Crud! If we’re sitting down, it’s going to be a long one. I thought.

“What do you think you want to be after college?” He asked.

“Well, I thought I’d like to be a wildlife photographer.” I said sheepishly.

He gave me a very concerned look and said: “David, nobody’s going to pay you to take pictures of bugs. What else have you come up with.”

“Maybe a charter boat captain?” I said. The conversation laid in a heading for the southern cross about that time. This was one of those talks I absolutely hated. I didn’t tell him I had no idea, that all I really ever wanted to be was a boat bum. Sure, I had lots of interests. Anything to do with boats was fair game. Looking at them, fishing on them, sailing them, building them, going out to that horizon was always on my mind.

My Dad was a hard worker and I had great respect, but he never really understood the raging fire he had ignited in me by taking me out to sea starting when I was about 11. Many years later, now, the fire is hotter than ever. I am Dave Ahrens and I am building Theresa II. The Albert Strange yawl found on page 142 in John Leather’s book, “Albert Strange, Yacht Designer, Artist”

I walk the 87 steps from the house to the shop as soon as I can pull myself away from the field. I love the open space the field gives me with the hills all around but being in the shop is where stuff happens. I flip on the lights and there she sits, awaking from a night of slumber. I cruise along beside her stroking her long keel as I head to open the big door at the other end of the shop. Turning back, I pause to admire her form sitting there on sawhorses. I am envious, really, her whole future ahead of her. Just a few months ago all her big pieces were separate on different tables. Now they are assembled. She is taking shape and lately I have noticed a quiet whisper as she points me to the next task at hand. This boat has a personality that is coming alive. I have heard many people describe their ownership of a classic boat as a stewardship. That is the way I feel with Theresa. Though she is not yet completed (barely started), I can feel her eagerness. She is already a valuable piece of history, a legend before her time, as if she has waited throughout her long existence as mere concept, patiently waiting for this chance to live her life.

Finding my ratty old desk chair, many years ago expelled from the house to serve in the shop, I have a seat beside her and get reacquainted with where I left off yesterday. Usually this involves checking to see what damage I may have previously inflicted. Hopefully, I won’t have to redo anything big. I have found that one can waste a tremendous amount of time by going very slow. Conversely, one can also waste a tremendous amount of time by going very fast. I seem to have a talent for getting ahead of myself, also a pitfall. So, I have worked out my plan of approach to any operation involving a saw or a grinder, or heaven forbit an axe. I first work out how I am going to fix it after I screw it up.

Today I am working on shaping the stern knee to the inside of the planking and there is a very real possibility I could stick my gouge in some part where I shouldn’t be sticking it. An embarrassing apology might be in order. Unfortunately, Theresa is not very squeamish in this matter. I have in the past, been quite happily grinding or gouging away and suddenly realize I am well past the line. And not a word from Theresa! But that is the beauty of epoxy construction. One can, in a pinch, just stick another piece on. (I know this is very uncool but in actual fact, it is a huge “save the day.”) Now this knee is just forward of the stern post and sits on the wood keel beneath where the engine will be. It is 42” long 10” wide and shaped like a big chunk of cheese. Because of the shape of the hull, it is flared heavily at the forward end and not so much at the back. A rolling flare if you can imagine. (This is worse than a rolling bevel, by the way.) In order to cut this shape, I need to make templates for the half and quarter stations between station 8 and station 10. This involves a lot of crawling around on the floor with sticks and squares and measuring things picking up various points, taking them to my body plan and drawing in six new stations, at least up to the top of the knee. I then make the templates out of 1/8” Plexiglas (acrylic). Larry Pardee, when he built Taleisin, made his templates out of brass. The problem with brass is you can’t see through it. So, I just lay the acrylic on my body plan and draw the line and cut it out. I don’t like making a template to make a template. Once I have these made it is a matter of grinding or chiseling away and holding up the template to check.

This brings up one of the “cons” of epoxy construction. Opposing wood directions combined with a rock-hard layer in between makes chiseling, not so fun. There is tearing, splintering and many trips to the sharpening station. Anyone who complains about this is absolutely right. So, the better option on a big job like shaping the knee (if you don’t want to go very, very slow) is the grinder with a flap disk or a carving wheel. The grinder, however, is a nasty, really nasty, tool to use in any shop you’d like to inhabit without wearing a dust mask. The grinder can also inflict great damage to Theresa very quickly if I happen to be thinking about fishing or sailing and quite frankly, I hate my grinder.

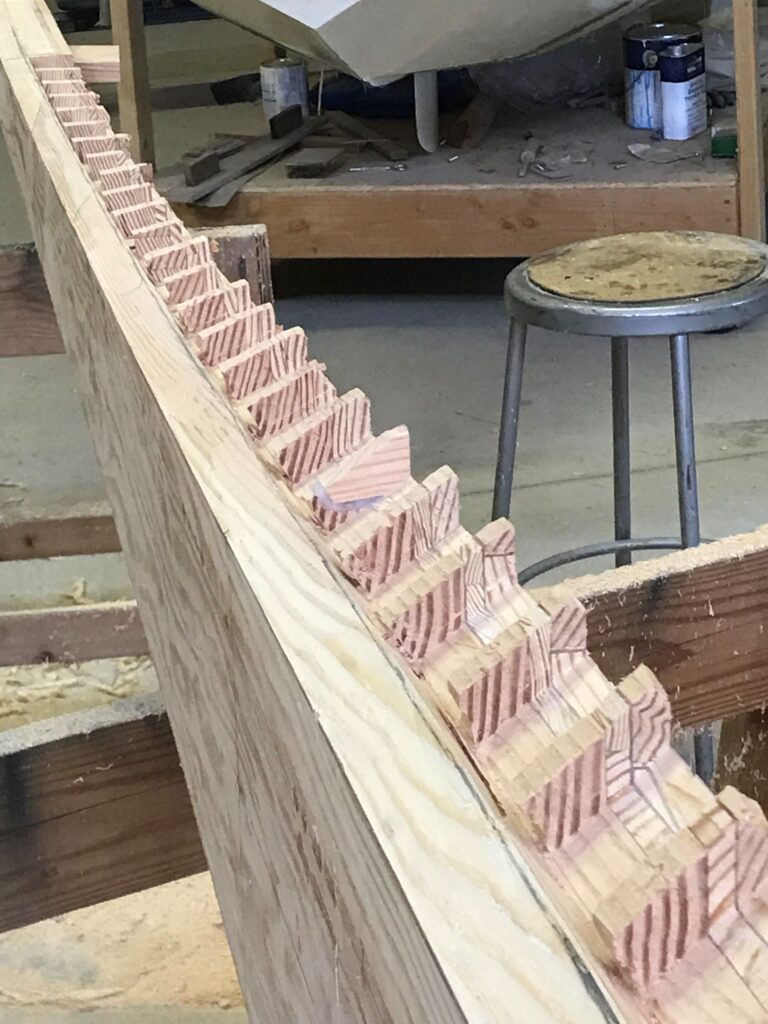

All the centerline “timbers” have been laid up using douglas fir and epoxy. I have picked the tightest grain I could find. This is not an easy task these days as trees are getting skinnier and skinnier. Most of the Douglas Fir so far in Theresa is super tight, old growth and clear, bought decades ago by my wife for me to make windows, doors and other house stuff. Of course, I bought way too much and over the years we have become very acquainted. I always really knew it would one day land in a boat and now it and Theresa are one. The hull is not going to be cold molded (three or four opposing thin layers.) My plan is for steam bent white oak frames on 7.5” centers and then double planked. This involves 2 layers cedar or maybe the inner plank of cedar and the outer one of douglas fir (much harder). These would be overlapping seams epoxied together and then 10oz cloth over the entire hull. Each plank would need to be spiled and fitted just as if it were traditionally built. It is essentially two carvel planking jobs on one boat. (Upon writing this, it just occurred to me that I may have picked the absolute most difficult way to build a boat.) The finished hull would be 7/8” thick and solid like a rock. It would survive being out of the water with little worries about drying out. Having your boat crack apart in the hot sun is never a good thing. I had thought about using a solid timber for the knee instead of laminating it but then having some of the centerline built with laminations and some with solid timbers could cause problems. I think the last thing you want in a keel structure is for some of the parts moving around inside a hull that will not move.

After about 30 minutes, using a 1” chisel and my gouge I have removed enough wood along the starboard side at station 8 ¼ to be sufficiently close with my template. It is amazing the difference in the shape of the flare just 6” away from the last one. When I finish the last one, I’ll take it outside and grind it smooth. It is much lighter than before. Then I will cut two mortises in the keel beneath it with tenons to tie it together. This is not really needed with the epoxy and keel bolts that will eventually go through it but hey, why not. Belt and suspenders… I sit it back in position and admire it from different angles. Nothing strikes me as weird so possibly It will not go in the scrap pile. Four hours have gone and I have gotten in a little more than 2 hours of work. Ridiculously slow I tell myself. I have to get faster. Oh well, I scoop up my chips off the floor and head for the door. Before I flip the off the lights I pause to look back. She didn’t speak to me during that whole time, I thought. Probably getting used to her new curves. I flip the light and shut the door. I wonder if she dreams, I thought with a smile as I walk my 87 steps back to the house.

Dave Ahrens

Email: dave@northshoreboats.pro