Theresa II is undergoing her transformation from a pile of lumber to a recognizable structure. It is finally warming up here after one of the worst winters I can remember. Fifty inches of rain and a foot of snow is just not what most of us in this area want to see. Forgive the whining. I know a foot of snow is peanuts for many but I’m just a South Texas kid, not used to such abuse. If there was anywhere to send a complaint I would do so. To make it worse, we had no power for almost a week and before then no internet or phone for 3 weeks.

Inside the shop Theresa sits upon her table patiently anticipating my first moves toward aligning her form molds. I can already see, as I move the forms into place, that they are not going to hit perfectly where they should. Some look great and some, not so much. Probably I expected this, I tell myself, quietly, trying not to spoil Theresa’s good mood. Actually, I did plan it this way, as I recall. I had cut the rabbets in the keel before I made the form molds and I cut them pretty far outside the line, just to be safe. They are about 1/8” to 3/16” undercut. (3 – 5 mm). Better undercut than over. Like most jobs, tolerances are determined according to functionality, and in this case, by what I can easily adjust and get away with. And always with a fearful eye on my scrap pile. The forms at stations four through seven sit under the long flat keel and it was easy to see on my lofting where they landed.

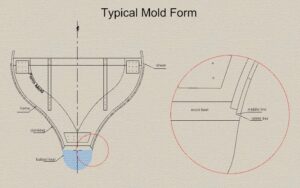

The forward and further aft forms land on the curved surfaces of the inside of the stem and horn timber, knee and stern post. In these areas it’s not so obvious since here the rabbet runs at a pretty wild and acute angle to the form. And, of course, to make it interesting, it’s all upside down. I’ve been wrestling with a sort of bewilderment on this issue for the last several days. This has been interesting and I guess even a bit fun. I can recognize a sort of thickness in my thinking which usually means I might be confused, though I am not ready to admit it. It’s sort of like telling yourself you’re NOT seasick. I think at some point in my history I became very bored with square corners and there is not a square corner to be found in Theresa. A little confusion here and there is a welcome friend. Oh, what fun this is. There are at least 100 things to adjust and it is only the right combination that will line everything up. Hack off the wrong thing and you may be sorry. I’m not stumped, I tell myself. There is a difference between being confused and being stumped. You’re only stumped if you have been telling yourself you’re not stumped for more than five days, and it hasn’t been that long yet. My shop chair is looking pretty comfortable, my head is starting to throb and a concerned look from Theresa is pushing me in that direction. It’s time to get back to basics. If there is anyone reading my posts that hasn’t yet concluded that I am a complete rooky please let it now be known. Though I have built 2 boats and worked on many more, designed piping for reactors, built houses and even made parts for the space shuttle, I have to say that the beautiful curves on Theresa have posed a special challenge. I am constantly torn between getting it right and getting it done. Unlike any other job I’ve ever done, this one has history, an added importance. So sometimes it’s best to take a step back and reacquaint yourself with your project. If there is any place to drag myself out of the weeds it is in my chair. Many a genius cognition has come from my chair. On my website I wrote an article about “Why this Boat” and I said that plowing through confusion is the hardest thing there is. Boy is that true. But it is the price of learning.

So, okay, the main and most basic thing to remember is that the structure must touch at all the right places on all the forms and the waterlines must all line up. And that, with the forms all plum, level and centered on the platform. The sheer at the stem head must be at waterline G and at the stern 13 ¼” below (above) G. (The top of my platform is at waterline G) Once I have that right, I’m there. Besides, in the end, all it really needs to do is look good and float. Perhaps I should add “and keep floating”. And guess what, as I shine my green laser on the side of Theresa all the waterlines line up as they should, again proving my lofting is correct. So, the lower (upper) parts are in the right place. I find that the keel is just teetering on one high place, which was rather obvious, in another spot I am on the wrong side of the line and up at the stem I had mistaken my sheer line with waterline G (how was it that I neglected to label these 2 marks?). How many countless hours had I spent measuring and remeasuring the same points and every time looked right past these blaring outpoints. Once adjusted it falls into place pretty much where it should. Standing back and looking at it was like sailing out of a fog bank. I would recommend this to anyone. (Quite the reverse an hour ago.) A beer? Yes, a beer sounds good.